Innovates your Parquet Production

TOP LAYER LAMELLAS

MACHINING LINE FOR THE PRODUCTION OF THE TOP LAYER LAMELLAS

The machining line for the production of the top layer lamellas is based on the prooven technology of the SCHROEDER-system for manufacturing solid wood parquet blocks and Lamparquet. For the special requirements of the production of top layer lamellas several properties were optimized. Instead of machining blocks with T & G, straight blocks, perfectly planed and cross-cutted on all sides, are manufactured. For this purpose only the tooling has to be different compared to classical or solid parquet blocks. For further detailed information, please refer to our pages for production lines for solid or classical parquet blocks. Of course the intermediate grading station SV and the transfer device TV-2 can be skipped because no face grading is necessary and there are no “right” and “left” hand blocks. In addition, the double cross-cut machine is just equipped for cross-cutting with 2 or 4 saw spindles, only.

In addition to the above mentioned line, a machine for splitting of the planed blocks is necessary. This splitting saw is available in various versions with 2, 3 or 4 saw spindles, each equipped with 1 - 5 saw blades, depending on if the planed and cross-cutted blocks shall be sawn into 2 lamparquet blocks or into 3 or more top layer lamellas. The use of circular saws reduces maintenance of the machine and especially of the tooling, low tool costs at very high capacities are further advantages. In addition, the small amount of operators must be taken into account. The complete line (incl. planers and cross-cutting) only needs 1 person for loading.

Finally the lamparquet blocks or the top layer lamellas are graded (selected) into different qualities. Top layers are either stored in a buffer stock or directly fed into the glue application and pressing system.

SPLITTINGSAW S-4

Splitting Saw S-4, S-4/2, S-4 XL

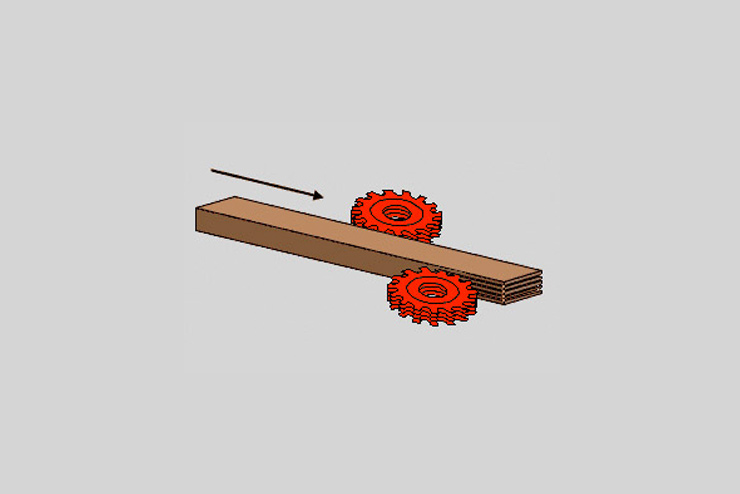

High capacity multiple splitting saw with 2, 3 or 4 vertical saw spindles for scoring and ripping of planed blocks into up to 3, 4 or more top layer lamellas (or 2 lamparquet strips 10mm) Splitting Saw S - 2with 2 saw spindles for Lamparquet or top layer lamellastypical kerf of the blades 2,2 - 2,6 mm.

Splitting Saw S - 4/2

Fully controlled 4 roller feeding system with pneumatic lift-off Precise height adjustement of the saw spindles with high resolution With safety large hood for reduction of noise and dust.

Splitting Saw S - 4/3

With 2 opposing scoring saw spindles and 1 splitting saw spindles Standard cutting kerf of the blades 2,2 - 2,6 mm.

Splitting Saw S - 4

With 2 scoring and 2 splitting spindles for highest efficiency in splitting top layer lamellas Equipped with super thin kerf saw blades 1,4 - 1,6 mm kerf