Innovates your Parquet Production

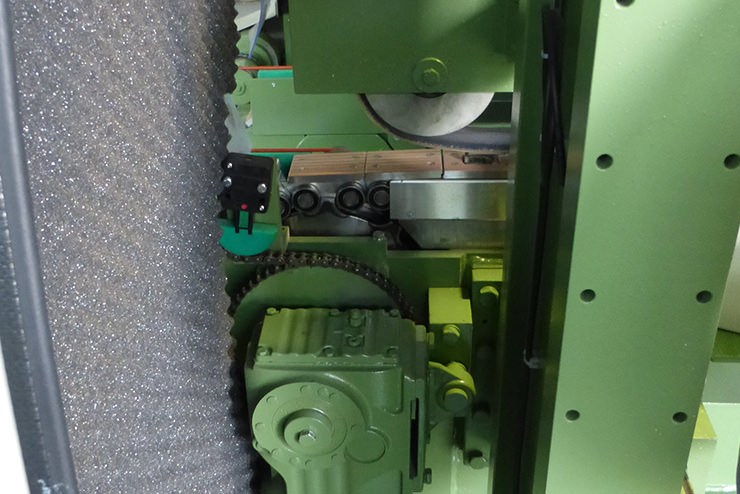

DOUBLE-END-TENONER PAKUE F

SPECIAL VERSION FOR HUNGARIAN POINT (FRENCH HERINGBONE)

Special version based on the precision Double- End Tenoner PAKUE F with roller guided feed chains additionally for Hungarian Point (French Heringbone Parquet with cross angle below 90°), for solid parquet or planks and for pre-finished multi layer parquet (engineered flooring).

Cross-cut angle adjustable (30° - 60° or 90°) by individual high precision Servo-drives for the feed chains (angle accuracy < 0,03 mm).All tool shafts with high precision spindle motors and hydro tool fixture.

As Double-End Tenoner with 3 or 4 spindles each per side for precise cross-cutting and endmatching with T&G as well as additional top face bevel (optional).

Capacity (90° square cut):

length 200 - 1.200 mm; max. 150 pcs. / min.

width 40 - 300 mm; thickness 8 - 30 mm (optional for lengths up to 4.500 mm).

Capacity (Hungarian Point 30° - 60°):

length 300 - 900 mm; max. 80 pcs. / min.

width 40 - 140 mm; thickness 8 - 30 mm

With “regular” hopper for solid parquet and planks as well as additional angular hoppers for “Hungarian Point” (r/h & l/h blocks).

Easy to operate via PLC touch panel; incl. calculation of infeed size (length), automatic tool compensation and calibration device.

With extended feed chains and integrated waste conveyor for off-cuts (specially for Hungarian point / French heringbone).