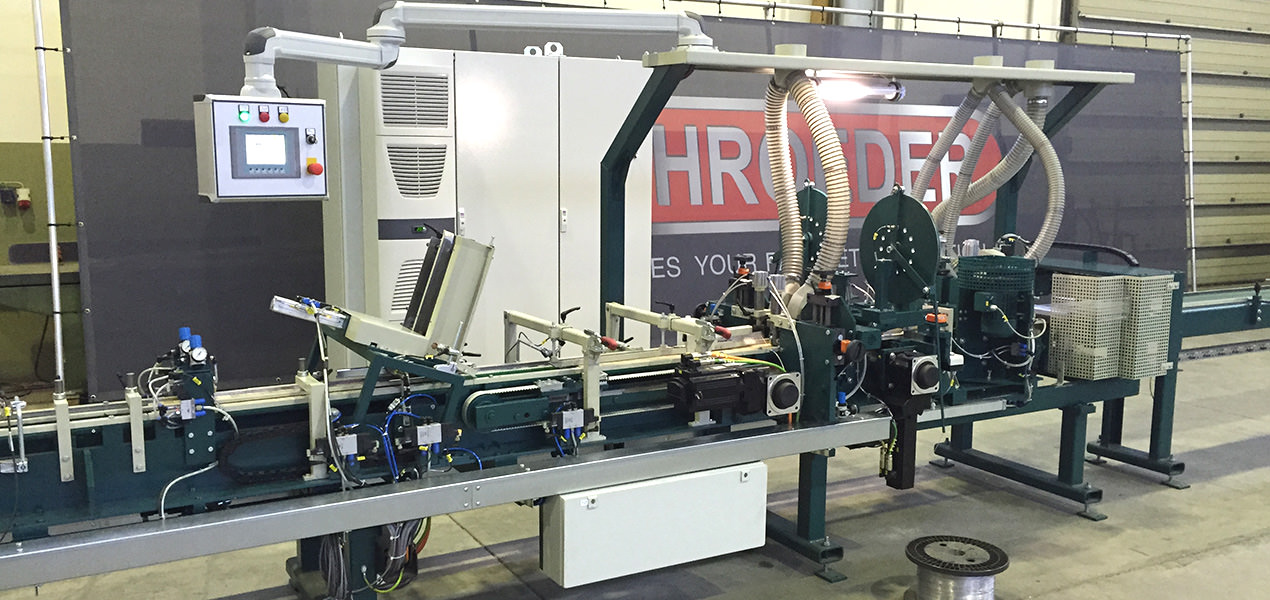

Innovates your Parquet Production

WIRE-CORD ASSEMBLY MACHINE DSV

HIGHLY FLEXIBLE LAMELLA-ASSEMBLY SYSTEM FOR CORE- OR BASE LAYER MATS

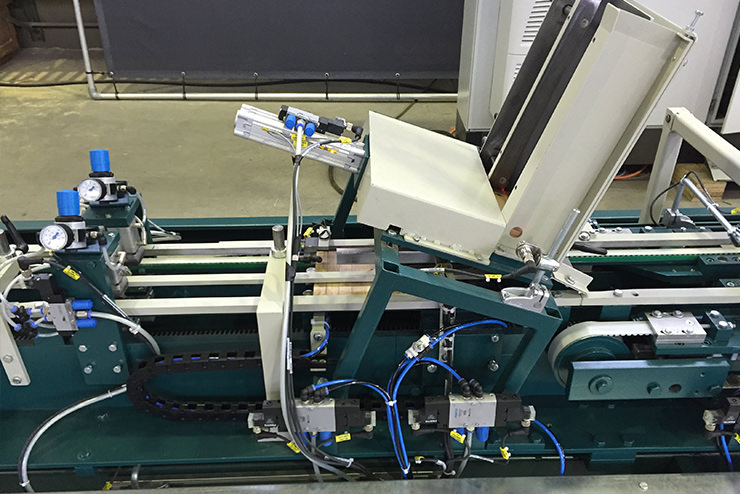

Automatic infeed of the slats out of mixing silo or stacking canisters or directly from slat production line. For calibrated or rough sawn slats, with Servo-drive units for feed and spacing (gaps).

Cutting of 2 - 4 grooves, automatic inserting and pressing of the wires (Aluminium) or plastic fibres (PA).

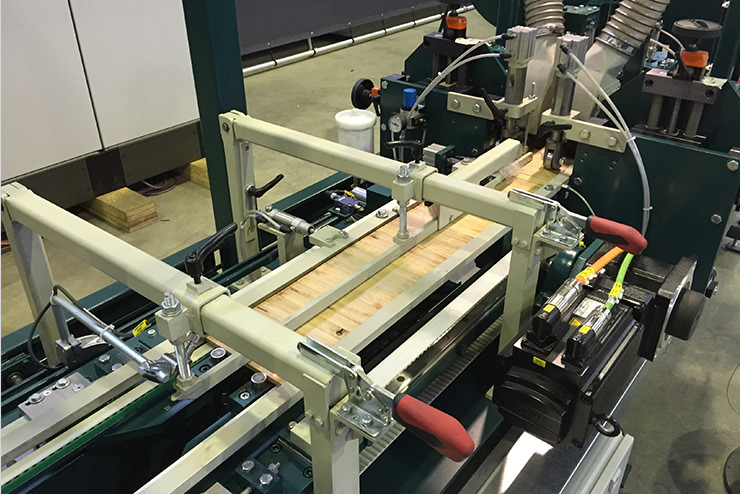

Synchronouos spacing of the mats to final length with fully variable spacing (adjustable gaps), finally wire cutting (drilling) or cross-cutting of the mats to final length with cross-cut saw.

Mat lengths fully variable by adjustable no. of slats per stroke (cycle), no of strokes (cycles) and spacing (gaps).

Mat-/ carpet-width (slat length) with motorized PLC-controlled setting, easy to adjust. On request with additional (wide) end-slats (hard- or plywood) autom. inserted from hopper.

Optional: automatic stacking units, e.g. on EURO-palette.

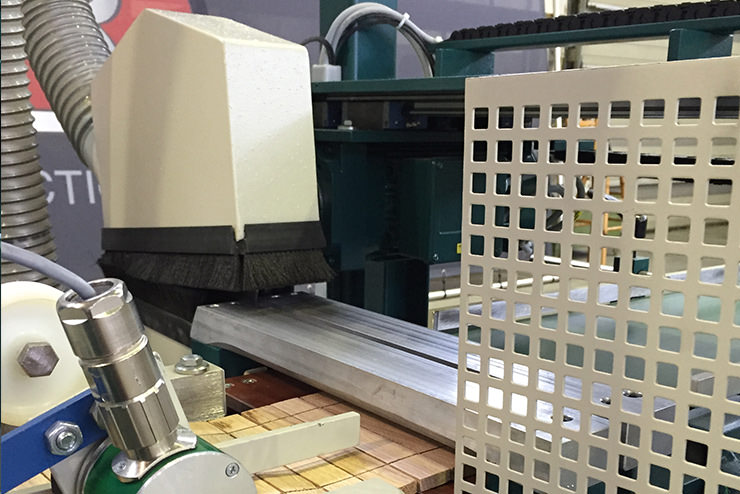

Groove cutting

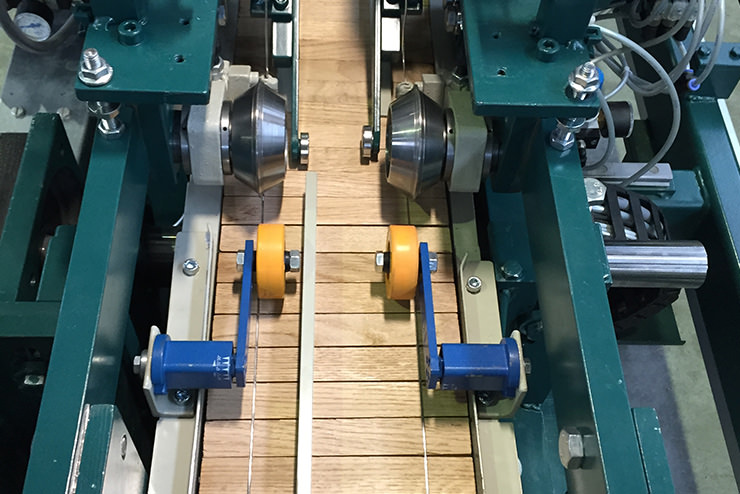

Wire inserting and spacing with gaps

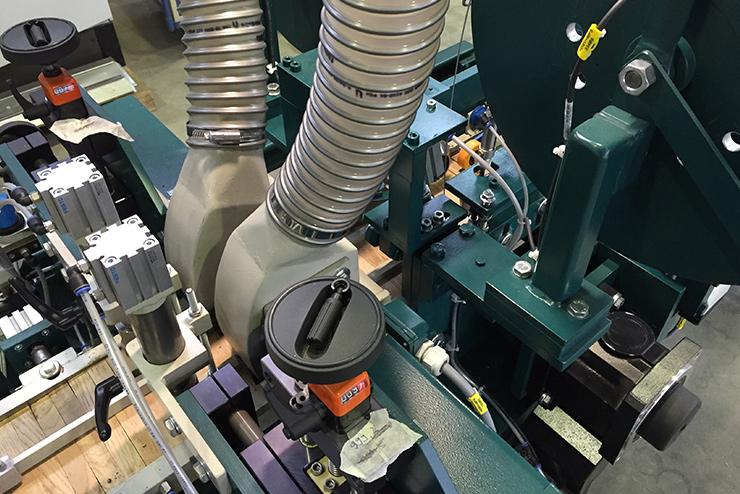

Wire cutting

Cross-cutting of end slats

Ready to use carpets / mats

Stroke (main pusher) available from 500 up to 1.500 mm,depending on main carpet lengths.

Capacity:

Slat lengths (carpet width) 120 - 500 mm

(calibrated or random/rough sawn);

Carpet length: ca. 200 up to 3.000 mm

(fully adjustable by no. of slats and gaps)

Slat width: 20 - 40 mm (kalibriert oder fallend/sägerauh)

Slat thickness: 8 - 12 mm (on request 5 to 20 mm);

Feed speed from 2 - 10 m/min. (ca. 400 qm / 8 h with 160 mm width)

End slats abt. 40 or 80 - 120 mm wide

(single- or triple width for cross-cutting)

Optional: carpets without spacing / no gaps.