Innovates your Parquet Production

2 PLY-PARQUET BLOCKS

Following the ecological trends of the last decades also the flooring market has turned to more "natural" materials. Only few years ago, textile floorings had a large share in the total flooring market, which is now slowly going back. Also all types of floorings, consisting mainly from plastics, cannot keep their market shares. Increasing shares are only recognized in stone and ceramics, parquet and other wood floorings as well as laminated floors using foils or rubber lamination on a wooden basis. According to specialists the prime time for laminated flooring is already gone in Germany, whereas all other types of wood flooring, fully made from natural products are said to increase even more in the next years.

Especially solid wooden parquet flooring and other types of parquet, 100% made of wood, are projected to have a very positive and long term market developement in future. The main reasons for this developement can be found in the increasing amount for renovation and reconstruction as well as the prooven positive effect to allergics. As the percentage of allergic persons in the european population is continuously increasing, requests for "natural" floorings will grow from year to year.

Besides these basic trends some further aspects are of importance. Born by architects and interior- designers "light-colored" wood species and visually "large" elements for flooring are timely. Small patterns and tropical hard woods have not been accepted for years. Due to the increasing percentage of "green" and "ecological" forrestry even in the countries of origin of tropical hardwoods these aspects are of minor importance today.

However, oak is still the most important species of wood, used for all types of wooden flooring. An increasing percentage can be recognized for beech and other types of light colored species.

The trend towards more "nature" for all types of floorings has also led to reduced shares of pre-finished products. Oiling and waxing are on the way to compete with UV- and other classical lacquers. The total ecological balance of wooden parquet floorings and therefore the customer acceptance will improove even more.

The significant properties of wooden parquet flooring are the reasons for its succes:

- long lifetime because of (multiple) re-sanding and finishing

- "healthy" flooring for allergic personsr

- re-growing material

- natural warmth

- many design variations (dimension, color, structure and pattern)

- environmentally friendly and recycable

- easy to use / care

- represents high living standards

- easy to install

The end-user assumes the ecological properties of wooden parquet flooring much better then those of all other types of flooring.

Top ranked are the oiled and waxed types of solid hardwood parquet strips, solid hard-wood parquet blocks and multi-layer types of hardwood parquet, followed by the laquered types of these parquet floorings. Only cork-flooring has a similar reputation from the point of view of the end user. Stone or ceramic, laminated types of flooring, textile floorings and other plastic floorings are ranked much lower.

A similar ranking is also given for the visual attractivity. Solid hardwood parquet blocks, multi-layer-parquet und solid hardwood strips are leading clearly in front of laminated floorings, stone, ceramic, cork, textile floorings and other plastic floorings.

Overall it can be stated that all those types of parquet flooring, only made of wood or wooden materials, will have a very prospective future.

A detailed analysis of future perpectives of the different wooden parquet floorings is only possible by separating between the various types:

- Mosaic-parquet

- Solid parquet blocks with tongue and groove (e.g. 12 - 22 mm)

- Solid parquet blocks without T/G (Lamparquet 10 mm)

- Solid parquet strips (parquet blocks over 800 mm length)

- 2-ply parquet blocks

- 3- or multi-layer strips

Due to large volumes of very cheap imports from eastern european countries and from the far east, an economic production of mosaic parquet in Europe is only possible with modern, productive and highly automated systems. The market is stable and reasonable changes cannot be expected.

Solid parquet blocks and strips with tongue and groove kept their market share (in %) within the last few years and the volume increased with the whole market. Improvements in productivity and quality offer a good potential for a further positive developement in the next years.

Due to the high requirements of Lamparquet regarding humidity of wood and ground to be laid on, it cannot be used for all applications. However in the Netherlands, Belgium and northern France as well as in Spain and Portugal it shows reasonable succes in extending volume.

The 2-ply block, youngest member of the wooden parquet flooring family, is now on the market since few years only and expected to have highest increase rates in share and volume. Specialists forecast a similar developement as for the 3-layer strips 10 -15 years ago.

Since then 3- and multi-layer strips increased in volume to the most important product of mass production wood flooring. Today, however, the world wide production capacity for 3-layer parquet has come close to the limit of demand. Therefore the price is now at a point of return.

Regarding the financial investments for the various wooden parquet floorings, the solid types are at a much lower level compared to any multi-layer type. In addition, the technology, necessary for the production of solid wooden types of parquet flooring, is not as sophisticated as for the multi-layer types. Therefore operators and in-house logistics do not need to be at a high level.

Besides this the distribution of large quantities of 2-, 3- or other multi-layer types of wooden parquet flooring requires a different marketing and selling system then any kind of solid wooden flooring.

Comparing 2-ply blocks and 3-layer strips, the investment volume shows essential differences. A complete plant for manufacturing 3-layer parquet planks incl. building must be calculated with at least 10 million € (12 million US $). The capacity of such a plant can be estimated with about 2500 sqm per day.

Such a high capacity is not useful for a plant for pre-finished 2-ply blocks. For such an application abt. 1.000 sqm / day are fully sufficient and can be calculated at about 4 - 6 million € (5 - 7 million US $).

Main disadvantage of the 2-ply block is the smaller dimension. Application of the blocks requires more time and effort compared to the larger dimension of 3-layer strips.

Besides this aspect the 2-ply block offers several advantages due to the special properties. 3-layer strips can only be produced as ships-deck pattern whereas the 2-ply block does not limit the pattern at all. Use of the 2-ply block for renovation and reconstruction is of great advantage because of the lower thickness of the blocks. Application (glueing) is as simple as with any other type of pre-finished wooden parquet flooring.

In addition the visual impression of the single block is better due to larger dimension compared to the surface elements of 3- or multi-layer strips. Typical lengths of the surface elements of 3-layer strips are between 250 and 400 mm. The 2-ply block usually shows lengths of 450 to 550 mm. This meets the timely "design" trend

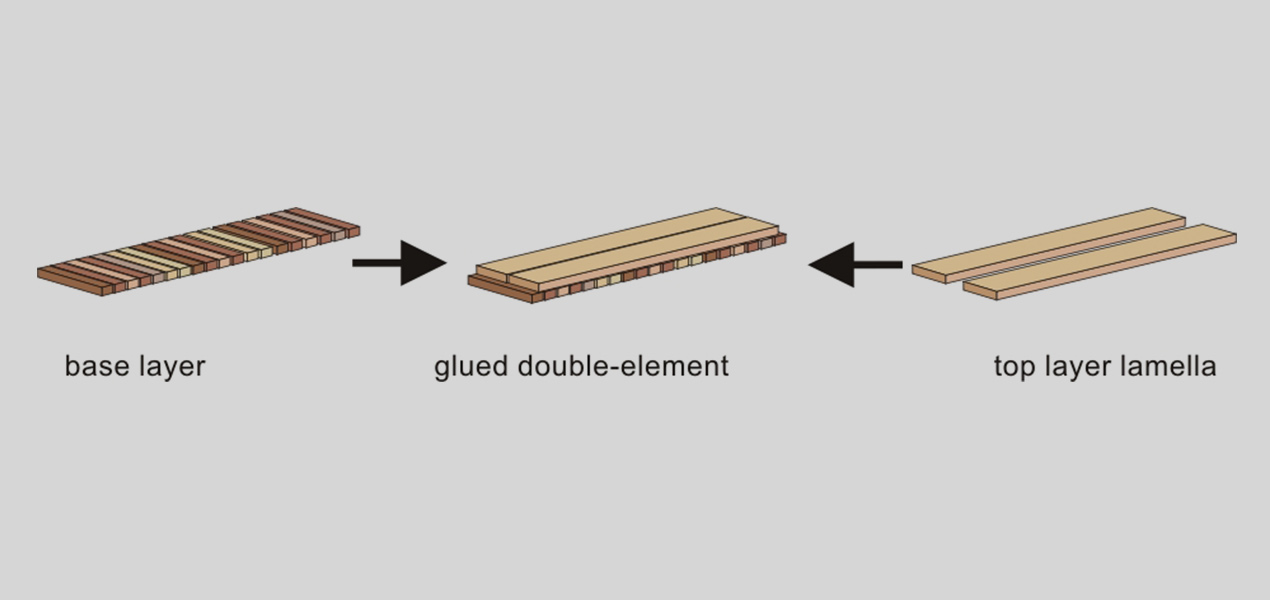

THE PRODUCT

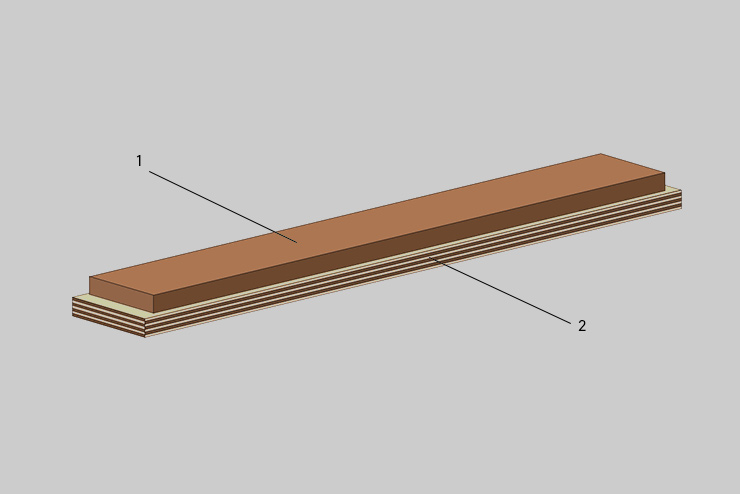

Type 1

Top layer (1) The top layer consist of a 3 - 6 mm thick lamella, made from hardwood like oak, beech, maple etc.

Base layer (2) The base layer consist of crossed hardwood or softwood slats, e.g. mosaic-parquet fingers, between 5 and 8 mm thick and approx. 16 - 23 mm wide.

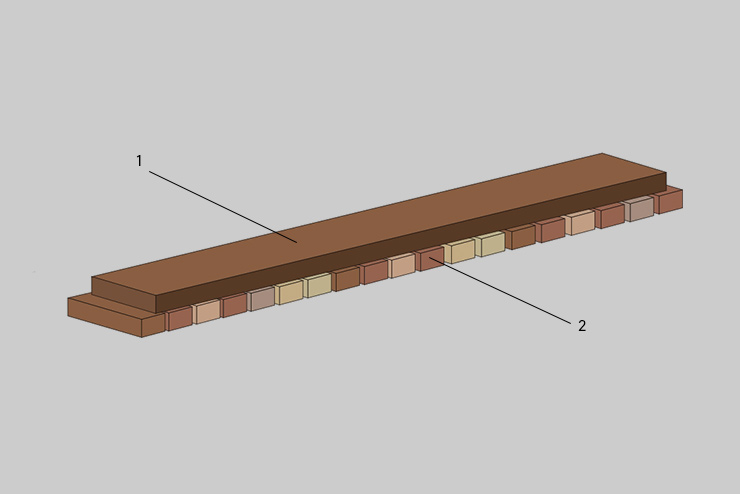

Type 2

Top layer (1) The top layer consist of a 3 - 6 mm thick lamellam made from hardwood like oak, beech, maple etc..

Base layer (2) The base layer consists of a plywood plate. Thickness of this plate is typically between 5 and 8 mm.

PRODUCT QUALITY

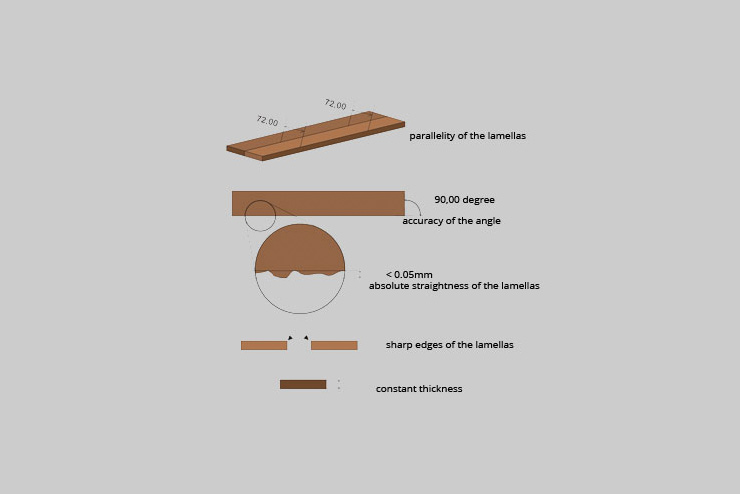

The product quality is determined by the quality of the top layer lamellas and the quality of the finish machining. In contrast to the 3-ply strip the tolerances of the top layer lamella are not of that importance for the 2-ply block.

Only the accuracy of thickness is relevant. Of course the single lamellas must not show any tensions from the kiln drying process.

1. Top layer lamellas

Other aspects:

no chipping

high surface quality

no bending (drying tensions)

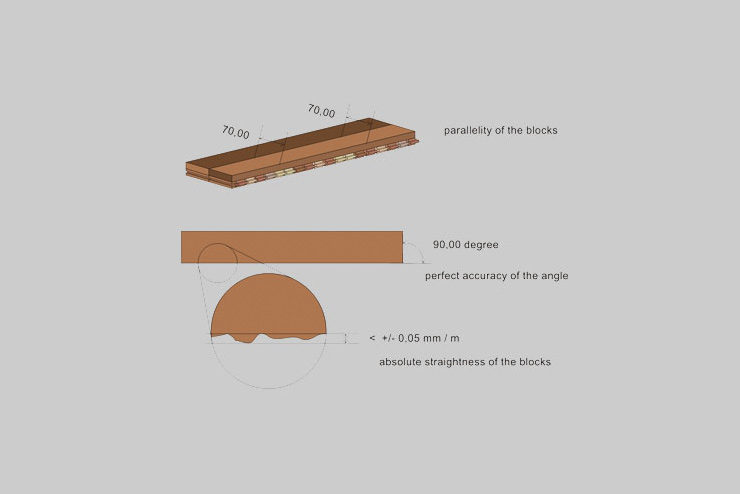

2. Parquet blocks

PRODUCTION PROCESS

The manufacturing process of multi-layer wooden parquet floorings must be differentiated in the following steps:

- 1. production of top layer lamellas

- 2. production of base layer

- 3. glueing / pressing

- 4. ripping / grooving

- 5. surface

Besides the quality of the wooden raw material the final product quality is determined by the following production steps:

- top layer manufacturing

- pressing

- surface finish and

- finish machining

Within these manufacturing steps precision and reliability of the machines is the most important factor. Regular and unexpected interruptions of the production due to machine stops must be avoided or minimized respectively.

Important for parquet manufacturers are:

- extremely precise

- very robust

- maintenance free and

- operator friendly machines

In addition, depending on the design of the parquet flooring, the different base layers are necessary. If slats (e.g. waste slats from the mosaic parquet production) are used, these slats must be produced first and then combined or connected to cords or mats. Only by connecting the slats to cords easy handling is possible and a uniform product quality is ensured. In addition, the various production steps become independent from each other and e.g. tool changes in a single machine do not stop the complete production.

GLUEING AND PRESSING

GLUEING AND PRESSING

Glueing and pressing of top layer lamellas and base layer can be done in various ways, depending on the type of base layer and the choosen glue technology. Besides the well known conventional white glue (cold glue) also more up to date techniques with so called hot melt glue (PUR-glue) are available.

The application of white glue is very useful, if large dimensions are pressed, e.g. if plywood panels are used for the base layer. In this case the glue is applied on the panels with rollers or jets, then the top layer lamellas are placed and the full package is loaded into the press. After pressing the panels are ready for further processes, like lacquering or sizing.

Of course this method can also be applied with modern hot-melt (PUR) glue, but fast hardening of this glue requires very fast handling and short processing time. Therefore smaller panel sizes, e.g. double-elements, are choosen, to reduce handling time. For these small sizes also smaller presses can be applied.

In case of slat cords or mats for the base layer, the mats are typically produced in the desired dimension (e.g. a double or triple element) and then either manually loaded into a hopper of the press or automatically fed into the press from the production of the cords.

Besides these process details, there is an important advantage of the PUR glue compared to white glue, which recommends the PUR glue especially for the 2-ply parquet block. Due to the chemical structure of the PUR glue, this glue will not become hard and brittle but remains elastic with high percentage of flexibility.

This allows even different types of wood (species) for top and base layer, without having a 3rd layer. In addition, the parquet block can be fully glued on the ground lateron. Therefore the pressing system, introduced on the following pages is specially developed for the production of 2-ply parquet blocks with PUR-glue.

At first the hot melt glue is applied on the base layer via heated jets, then the top layer lamellas are placed and aligned. The top layer lamellas typically are piled in hoppers by hand, a direct infeed from the lamella production is not very useful as the lamellas have to be graded for color and quality, first. Only in case of computer controlled automatic grading systems, this direct infeed into the press is possible.

Then the elements are pressed for about 20 - 30 secs. until the glue is hardened to nearly 80 % of the final value. After pressing the elements are transported out of the press and automatically stacked to piles. For best quality the pressed elements should be kept in stock for at least 24 h, during this time the glue can develop its full hardness for the following processing steps (sanding, ripping, lacquering and finish machining).

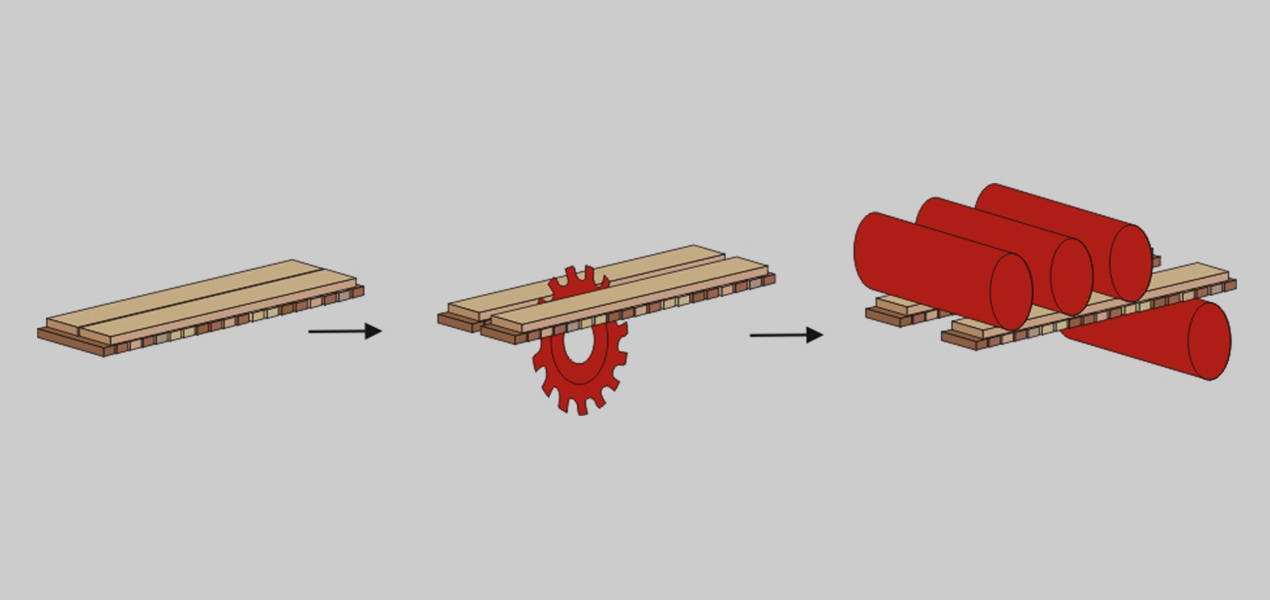

RIPPING / GROOVING

After glueing and pressing of top and base layer the following processes depend on the type of base layer. In case of crossed slats as base layer (type 1) the blocks were produced in double or triple width. These double or triple elements have to be ripped into single blocks in the rip saw TRS and sanded on top and bottom (calibrated).

With plywood base layer (type 2) the blocks are produced either in large panels or also as double or triple elements. The large panels can be kept in their dimension, handling is easier and efficiency of the sanding and lacquering line is higher.

However, due to the following machining steps (ripping, cross-grooving and tongue & groove machining frequent handling may lead to damages of the lacquered surface. As an alternative, the panels can be cut into the block size, the following production steps are corresponding to the parquet block type with crossed slats.

In addition plywood based parquet blocks must be cross-grooved at the back side with the grooving saw VNS to increase flexibility of the final product. This flexibility is one of the main advantages of 2-ply parquet blocks and the cross grooving should be done before sanding (calibrating). Chips and dust from the cutting process are eliminated, therefore also the ripping process should be placed in front of the sander.

The sanding process is absolutely necessary to prepare the surface for lacquering. Sawn or planed surfaces cannot be used for lacquering.

SURFACE

After pressing and glueing the single blocks - in case of a large press also the pressed panels - can be sanded and pre-finished (lacquered). Typically multistage systems with intermediate sanding are applied. Based on todays UV-lacquers a complete line consist of several roller coaters and the respective drying sections (UV-lamps). At first a 2 layer base lacquer and a possible filler is applied and UV-dried (hardened) individually.

Following this the lacquer is sanded before the next lacquer layers can be applied. Simple lacquering systems then use the above mentioned application systems for the base layer lacquer also for the finish lacquer. In this case the parquet blocks are sent through the roller coaters and drying sections again. In the final drying station the lacquer is fully dried (hardened).

However, complete lacquering lines for higher capacities typically show another set of 2 (or 3) apllicators (roller coaters) and the respective drying sections (UV-sections) for the finish lacquer. Additional handling for the second pass are no longer necessary, in addition any danger from dust contamination can be reduced to a minimum.

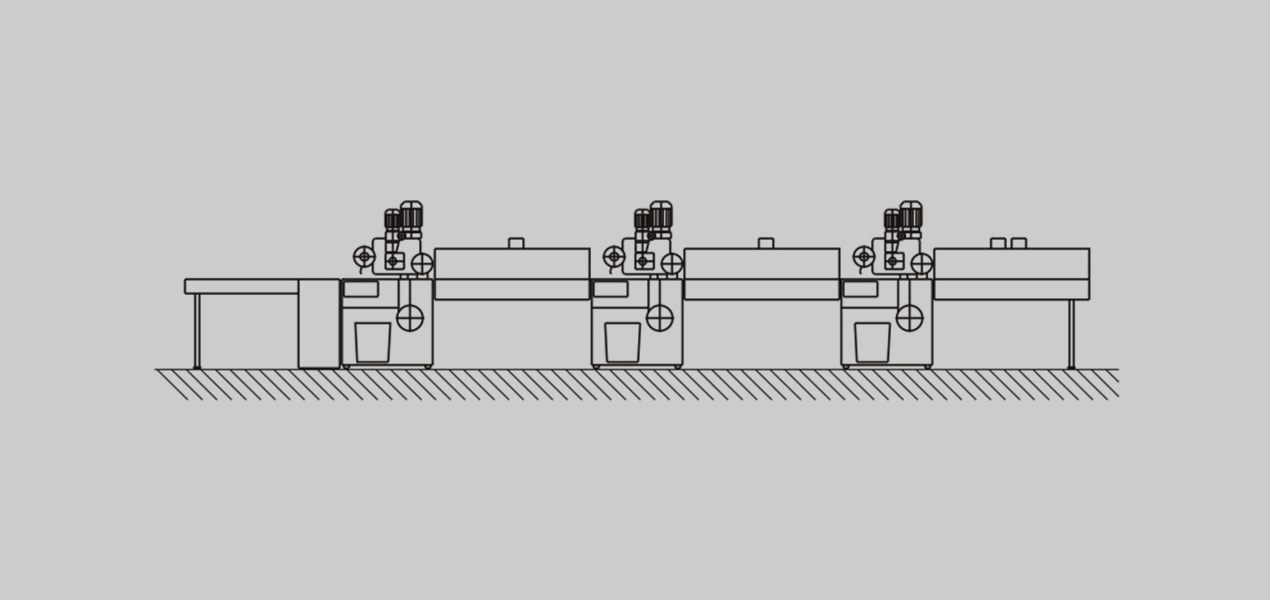

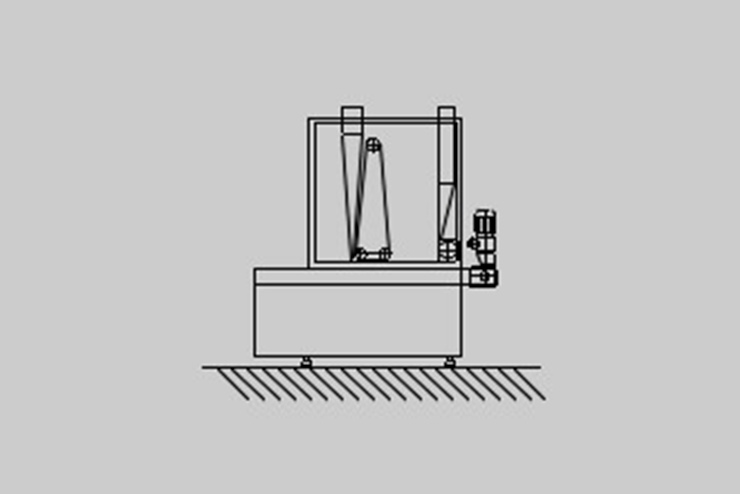

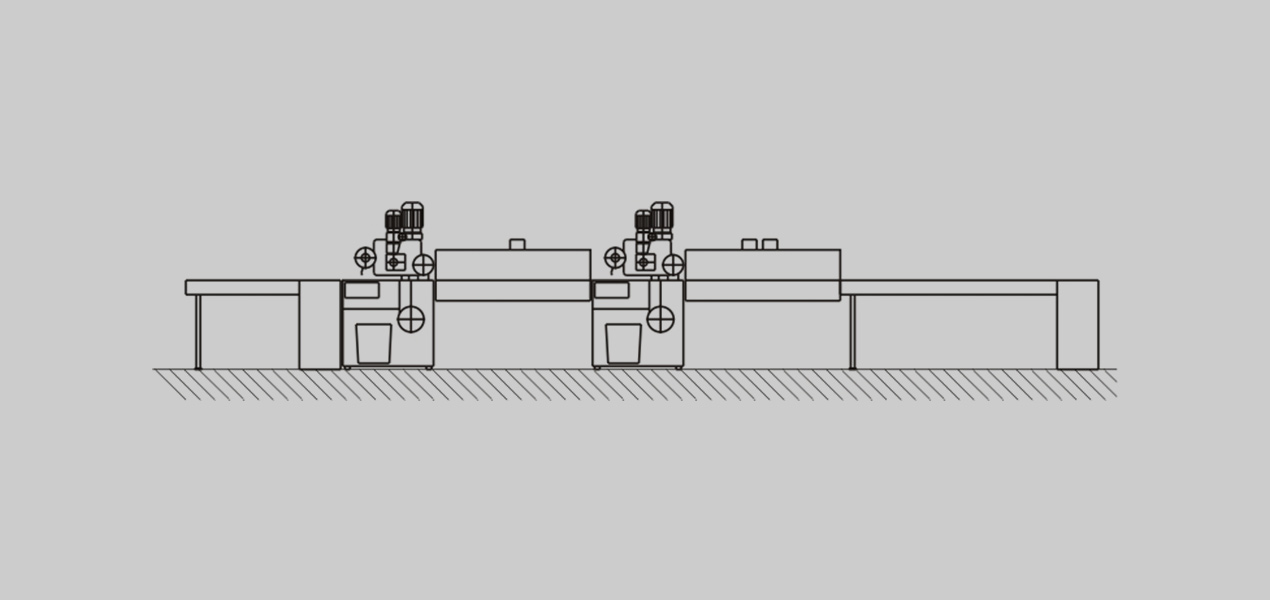

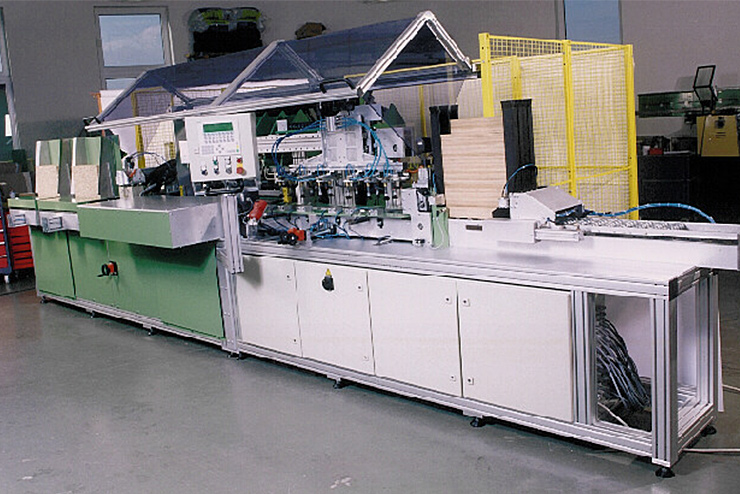

PUR DRUM-PRESS

TRP 1250 / 1500

Pressing length 1250 / 1500 mm

Pressing width 160 / 250 mm 160 / 250 mm

Infeed of base layers into hoppers (left side) with following glue application

Infeed of top layer slats into hoppers (right side)

TRP (small version)

Pressing length 500 - 600 mm

Pressing width 160 (max. 200) mm

Infeed of base layers into hoppers (left side) with following glue application

Infeed of top layer slats into hoppers (right side)

TRP 600 (small version)

Pressing length 500 - 600 mm

Pressing width 160 (max. 200) mm

Infeed of base layers into hoppers (left side) with following glue application

Infeed of top layer slats into hoppers (right side)

FUNCTIONS

- Infeed of top layer lamellas via hopper or conveyor,

- Infeed of base layer mats (or other type) via hopper or conveyor,

- automatic glue application (hot melt glue),

- placing of top layer lamellas on glued base layer,

- accurate position control of top layer lamellas,

- pressing with 12 - 18 kN / cm² (adjustable) and

- automatic outfeed with conveyor belt.

A typical production line contains either 2 small version presses or 1 large version. The main differences between the 2 versions of the press are the capacity and the option of producing large elements. Max. block length for the small version is 600 mm, the large version offers up to 1200 (1500) mm length (or 2 resp. 3 pieces 500 mm long in a row).

No. of pressing stations: 6

cycle time per station:

4 - 6 sek. (adjustable, according to glue type)

pressing area (per sation):

max. 0,10 qm (large version max. 0,37 qm)

max. part dimensions:

Länge: max. 600 mm (large version: max. 1200 / 1500 mm)

width: max. 200 mm (large version: max. 250 mm)

CAPACITY

Version 600 (base layers 160 mm wide): 12 double elements/min.

= about 48 qm / h (about 70 x 490 mm)

or

10 single elements/min.

= about 42 qm / h (about 120 x 500 mm)

Normal-Version, Tragschichten 200 mm breit:

12 triple elements/min.

= about 62 qm / h (about 60 x 480 mm)

or

12 double elements/min.

= about 70 qm / h (about 90 x 540 mm)

or

10 single elements/min.

= about 42 qm / h (about 120 x 500 mm)

Version 1250, base layers about 160 mm wide:

20 double elements/min. = about 83 qm / h (about 70 x 490 mm)

or

10 single elements/min. = about 94 qm / h (about 130 x 1200 mm)

Version 1250, base layers about 250 mm wide:

20 triple elements/min. = about 123 qm / h (about 70 x 490 mm)

or

10 double elements/min. = about 173 qm / h (about 120 x 1200 mm)

Version 1500, base layers about 160 mm wide:

30 double elements/min. = about 123 qm / h (about 70 x 490 mm)

or

10 single elements/min. = about 94 qm / h (about 130 x 1200 mm)

Version 1500, base layers about 250 mm wide:

30 triple elements/min. = about 185 qm / h (about 70 x 490 mm)

or

10 double elements/min. = about 215 qm / h (about 120 x 1500 mm)

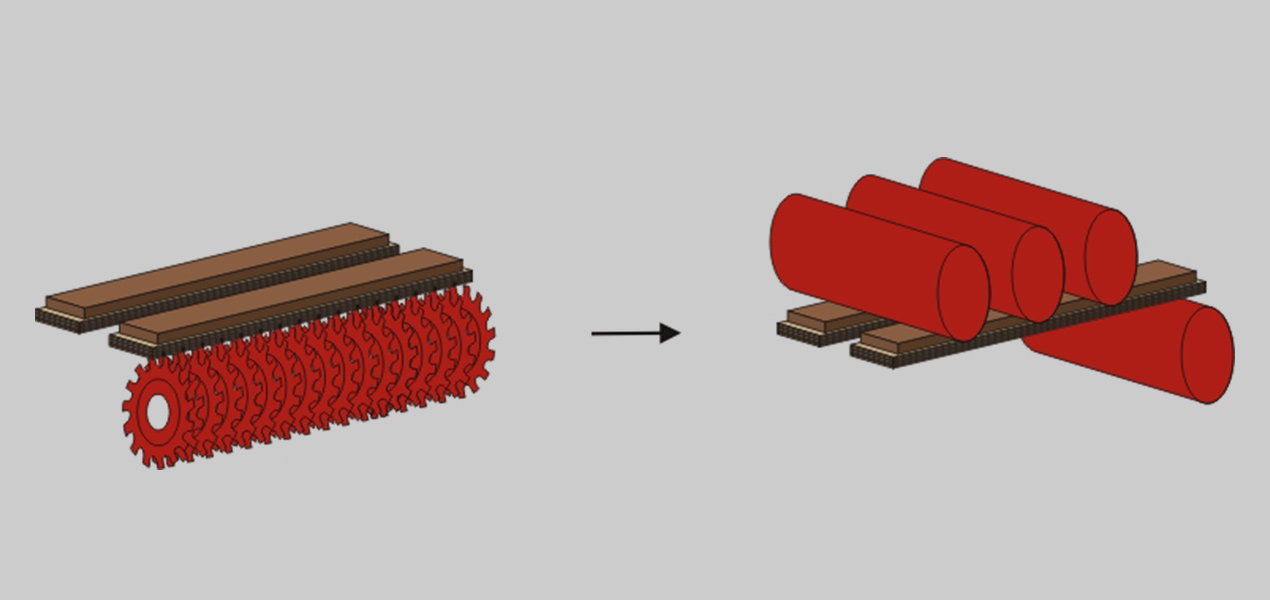

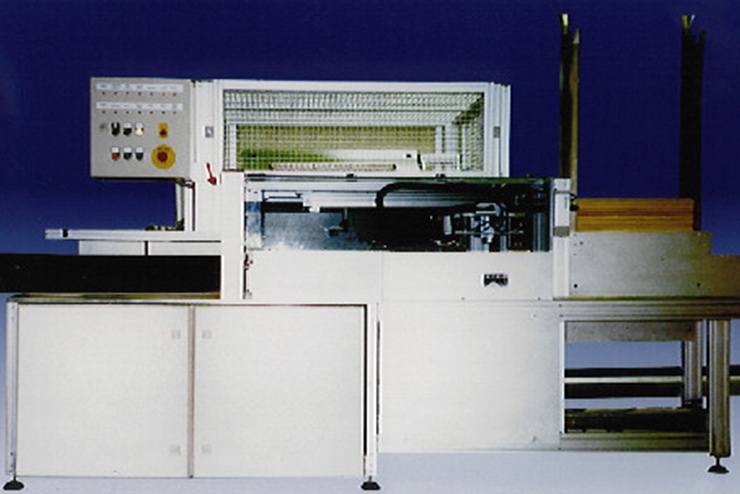

CROSS-GROOVING

Grooving saw VNS

Under-table saw spindle with plug in shaft over full length.

Pneumatic feed system Equipped with up to 25 TC-tipped saw blades for cross grooving of long blocks

Working width: 600 mm (on request up to 1000 mm)

Groove depth: 0 - 8 mm (on request up to 18 mm)

Feed speed: 0 - 8 mm (on request up to 18 mm)

Saw blades: >200 x 3,0 /2,0 x 65 mm, 48 teeth

Power: 11 kW (on request 18,5 or 22 kW)

Air consumption: max. 450 NL / min. bei 6 bar

Rip saw TRS

- Aufteilen der Mehrfach-Elemente nach dem Pressen in Einzelstäbe

- Einzug durch seitliche Riffelwalzen mit pneumatisch regelbarer Andruckkraft

- Automatische Ausrichtung am seitlichen Führungslineal

- Vorschub durch oberes 3-fach Walzensystem mit pneumatisch geregeltem Andruck