Innovates your Parquet Production

FINISH PROFILING

Profiling is the final step of the complete production process and determines the product properties. Therefore, all machines must be extremely precise and realiable.

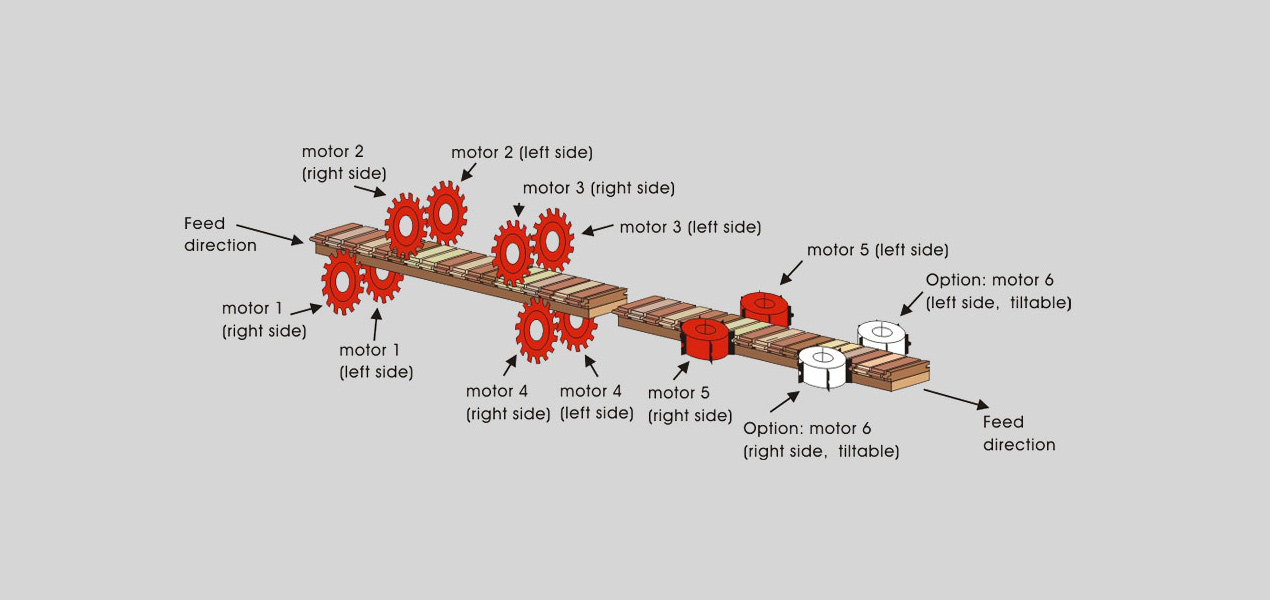

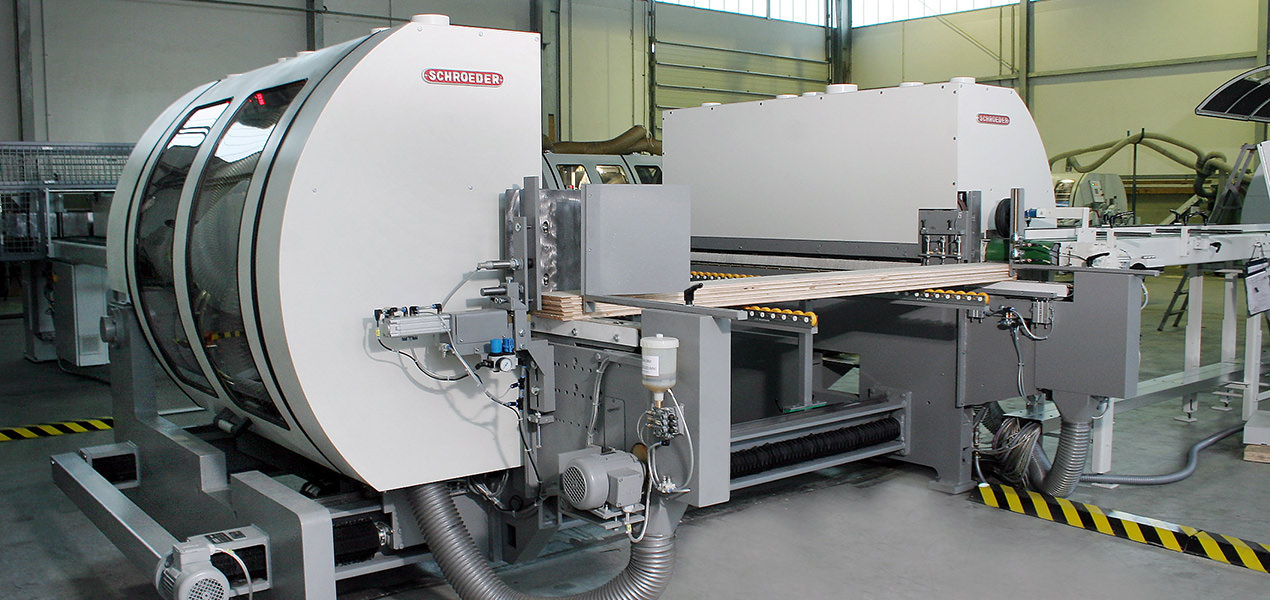

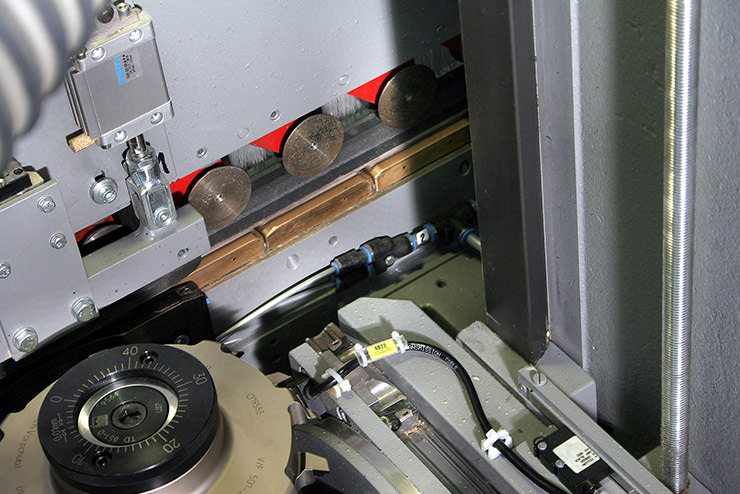

Lengthwise tongue and groove machining of the blocks is made on a specially designed profiler DUO 6 F (up to DUO 12 F) with 2 heavy bottom feed chains (with chain plates/pads) with integrated precision guide to ensure highest possible accuracy. Like in all DET’s one feed chain system is equipped with motorized width adjustement with PLC-control.

This allows wood widths from 57 - 250 mm and perfect support close to the profile. To obtain a product without any edge-chipping or tear-out the parquet blocks are precut by up to 4 scoring saw spindles each per side, in front of the two side cutter spindles.

Even cross grain wood of the base layer is machined accurately without chipping and a large variaty of profile designs is possible. For special profiles, e.g. “clic”, etc., up to 6 additional saw- or profile cutter spindles (even 2 x 90° universal or jumping) are available as option. Due to the transport of the parquet blocks on the coated feed chain plates, chips and splitters cannot damage the lacquerd surface at all.

For un-finished products (e.g. pre-sanded or base-coated material) a special version of our parquetry planer (type Pake 70 FS) is possible. With 4 saw spindles and 2 cutters, it offers the same level of accuracy at significal lower investment.

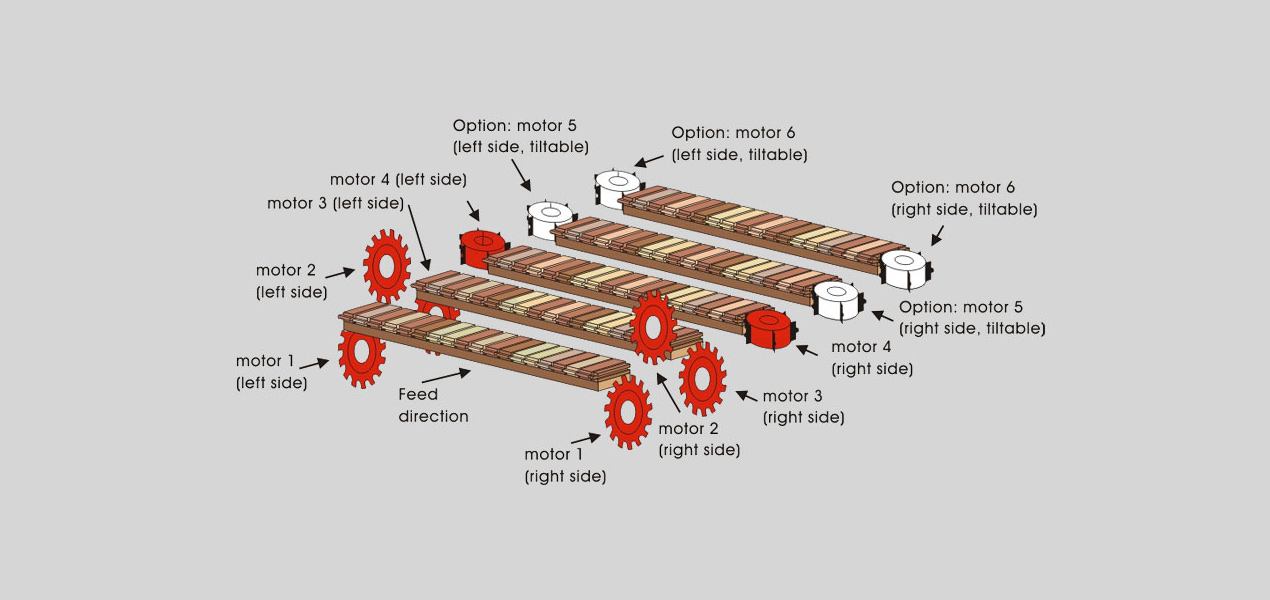

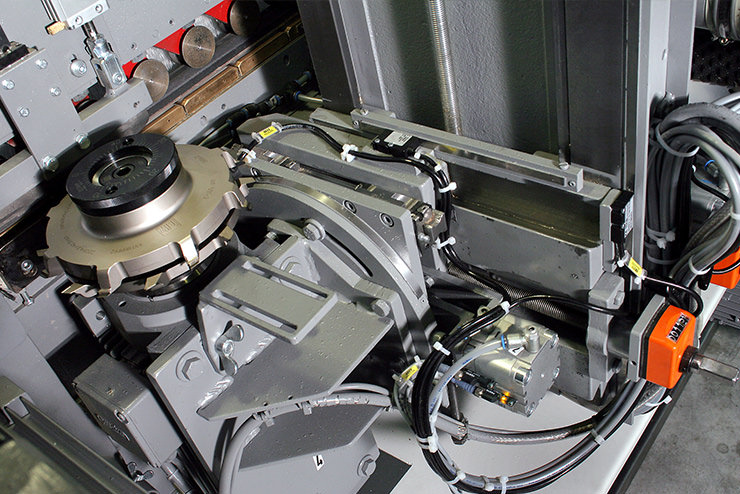

Machining of the cross ends is made in the double end tenoner type PAKUE F. The blocks or strips are placed on guided feed chains with rubber coated chain-plates, which ensures perfect guidance without any risk of damaging the pre-finished surface.

Depending on the requirements of the product and/or the profile (e.g. "clic"- or "snap"-profiles), up to 10 spindles (5 per side) are available. Machines with 8 or 10 spindles are equipped with an extended frame. During profile machining, the blocks are supported by air-cushion steel bars to ensure an optimum accuracy for the profile.

PROFILER DUO 6 - 12 F

Finish profiling

Lengthwise profiler with 2 bottom (guided) feed chains with coated plates for highest accuracy, specially designed for profiling parquet. Heavy feed chains with roller-bearing guide in specific design with capsulated bolts, individual needle roller bearings and coated chain plates. Chain width 30 mm (each), min. wood width 65 mm (depending on profile).

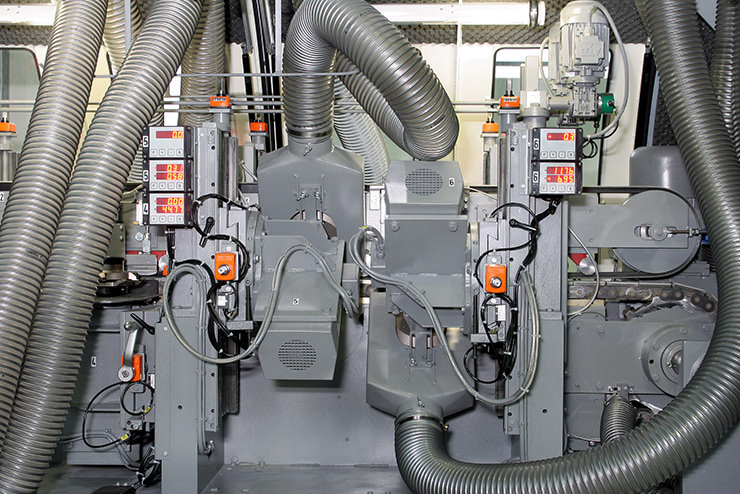

Large sound-proof and safety hood for reduction of dust and noise < 85 dB/A (without dust exhaust system) Integrated cleaning and blowing system with dirt extraction and dust exhaust for the feed chains Direct linear length measuring systems (res. 0,005 mm) with digital displays (0,01 mm) for all spindle axes 3 - 6 spindles per side (DUO 6 F up to DUO 12 F).

Upper v-belt pressure systems for perfect straightness and accuracy of the T&G profile PLC-controlled, motorized width adjustement and vertical position control of the pressure beams Sophisticated infeed system for parquet blocks and planks with top layer alignment ensures optimal straightness.

Compact spindle setting, all shafts with high precision direct driven spindle motors and frequency converters (programmable spindle speed, 7.200 rpm and 6.000 rpm are pre-set) with rotation control. Horizontal saw shafts (even at 60 mm wood width), for chip-free and precise edge-cutting .

Ideal for fast profile changes, e.g. from 2-layer parquet blocks to 3-layer planks , etc. Change of product width (e.g. from 60 to 250 mm) within 30 seconds.

No compromizes with 45° cutter spindles required.

Technical specification:

DUO 6 F: 4 saw shafts and 2 cutter spindles,

DUO 8 F: 4 saw shafts and 4 cutter spindles,

DUO 10 F: 6 saw shafts and 4 cutter spindles,

DUO 12 F: 6 saw shafts and 6 cutter spindles

or 8 saw shafts and 4 cutte spindles

All cutter spindles as 2 x 90° universal units (optional)

Spindle motors:

4,5 and 6 kW, optional up to 7,5 kW,

Feed motor:

5,5 kW (optional 7,5 kW) for feed speed 15 - 100 (120) m / min.

Wood length (250) 350 - 1200 (2500) mm

Wood width (60) 65 - 250 (310) mm

Wood thickness von 6 - 25 (30) mm (depending on tooling)

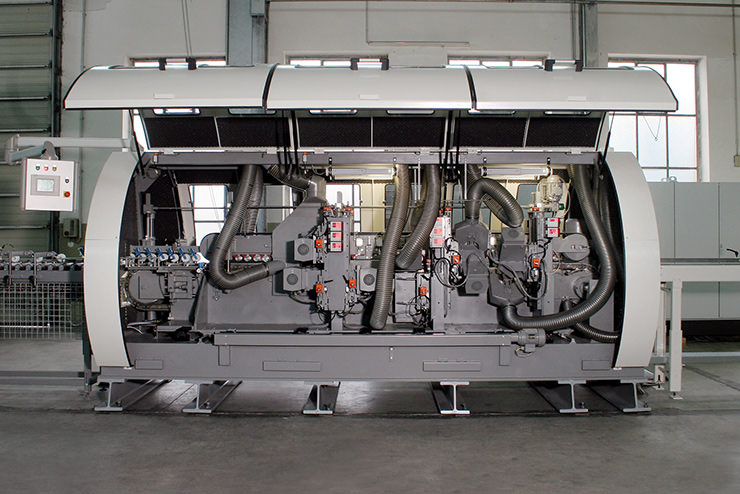

DOUBLE END TENONER PAKUE 6 F - 12 F

Double End Tenoner - specially designed for profiling pre-finished parquet Heavy, guided feed chains with capsulated bolts, individual needle roller bearings and coated chain plates. Upper v-belt pressure systems for perfect 90° angle quality (top layer blocks) or profile accuracy (pre-finished parquet).

Optimzed chain cleaning and greasing system with dirt extraction and dust exhaust for the feed chains - on request with rotating brushes. Automatic hopper feed system with integrated lifting device or clamping unit for the parquet blocks or planks.

Technical specification:

PAKUE 4 F: 4 saw shafts (for top layer blocks)

PAKUE 5 F: 3 saw shafts and 2 cutter spindles

PAKUE 6 F: 4 saw shafts and 2 cutter spindles

PAKUE 8 F: 4 saw shafts and 4 cutter spindles

PAKUE 10 F: 6 saw shafts and 4 cutter spindles

PAKUE 12 F: 6 saw shafts and 6 cutter spindles

All cutter spindles as 2 x 90° universal units (optional)

Spindle motors: 4,5 and 6 kW, optional up to 7,5 kW

Feed motor: 3 kW (optional 4 kW)

for feed speed: 30 - (100) 160 blocks / min.

Wood length: 200 (300) - 1200 (3500) mm

Wood width: 50 - 230 (310 / 500) mm

Wood thickness: 6 - 25 (30) mm (depending on tooling)

Compact spindle setting, all shafts with high precision direct driven spindle motors and frequency converters (programmable spindle speed, 7.200 rpm and 6.000 rpm are pre-set) with tool rotation control Large sound-proof and safety hoods for reduction of dust and noise Direct linear length measuring systems (res. 0,005 mm) with digital displays (0,01 mm) for all spindle axes (PAKUE 6 F and higher) .

Optimized, specially coated support bars with air-jets at the cutter positions, on request with TC-inserts and/or with additional pressure shoes for specific profiles ("clic" or snap) PLC-controlled, motorized length adjustement and vertical position control of the pressure beams.

On request with jumping spindles (up/down saw spindle or in/out cutter spindles) with linear ball bearing guides ensures chip-free profiling for solid or multi-layer parquet.

Depending on version with intergrated waste conveyor (for cut-off's in solid parquet or top layer blocks) or hoggers (for chipping at profiling pre-finished parquet) .

In right-hand or left-hand version, as requetsed by line layout.